- Description

Description

Better is possible

We know we can create a material that stands up to everyday use, without taking it out on the planet. Protecting our climate, without sacrificing standards. With environmentally responsible materials that deliver exceptional customer experiences.

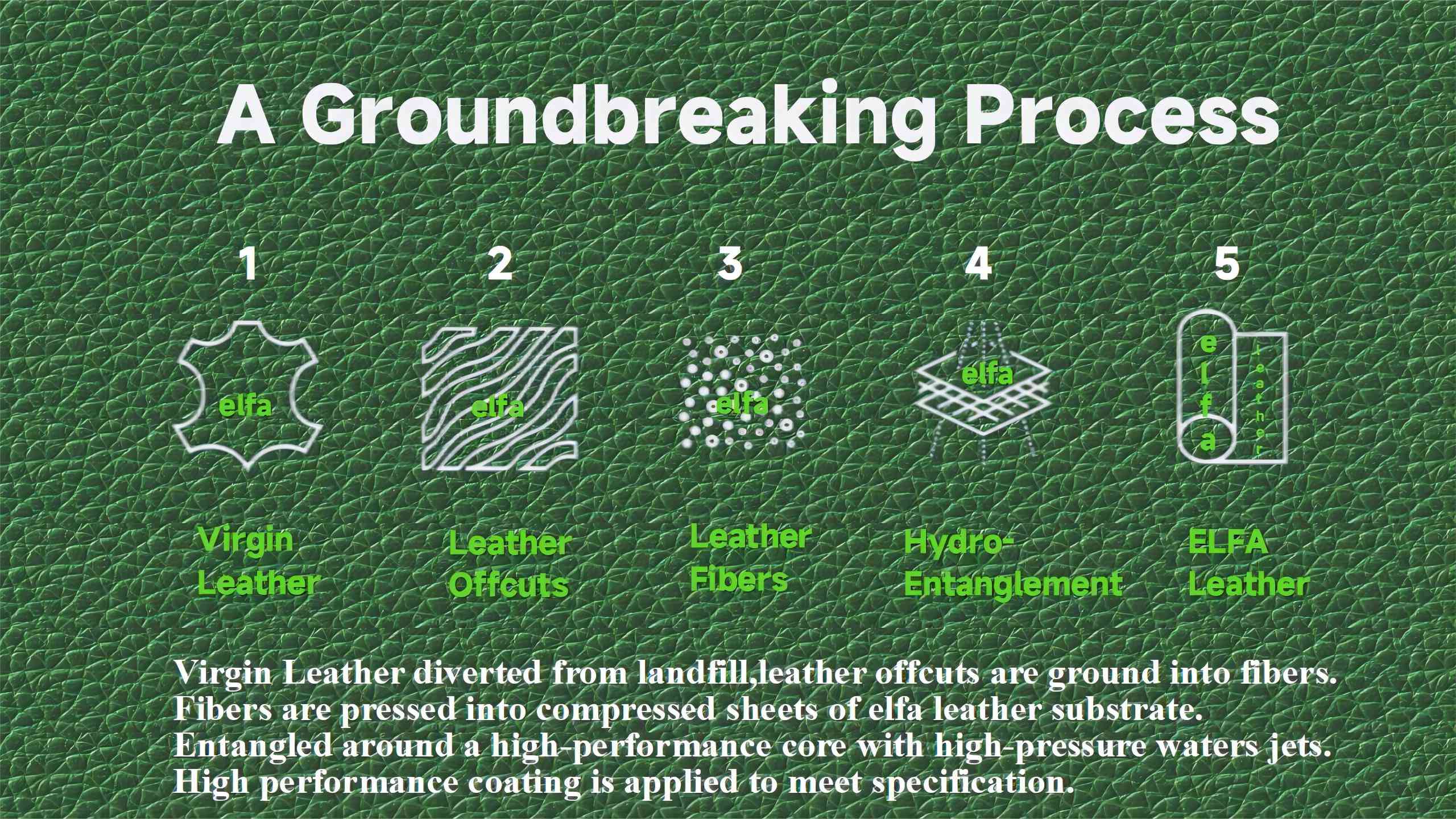

How it’s made

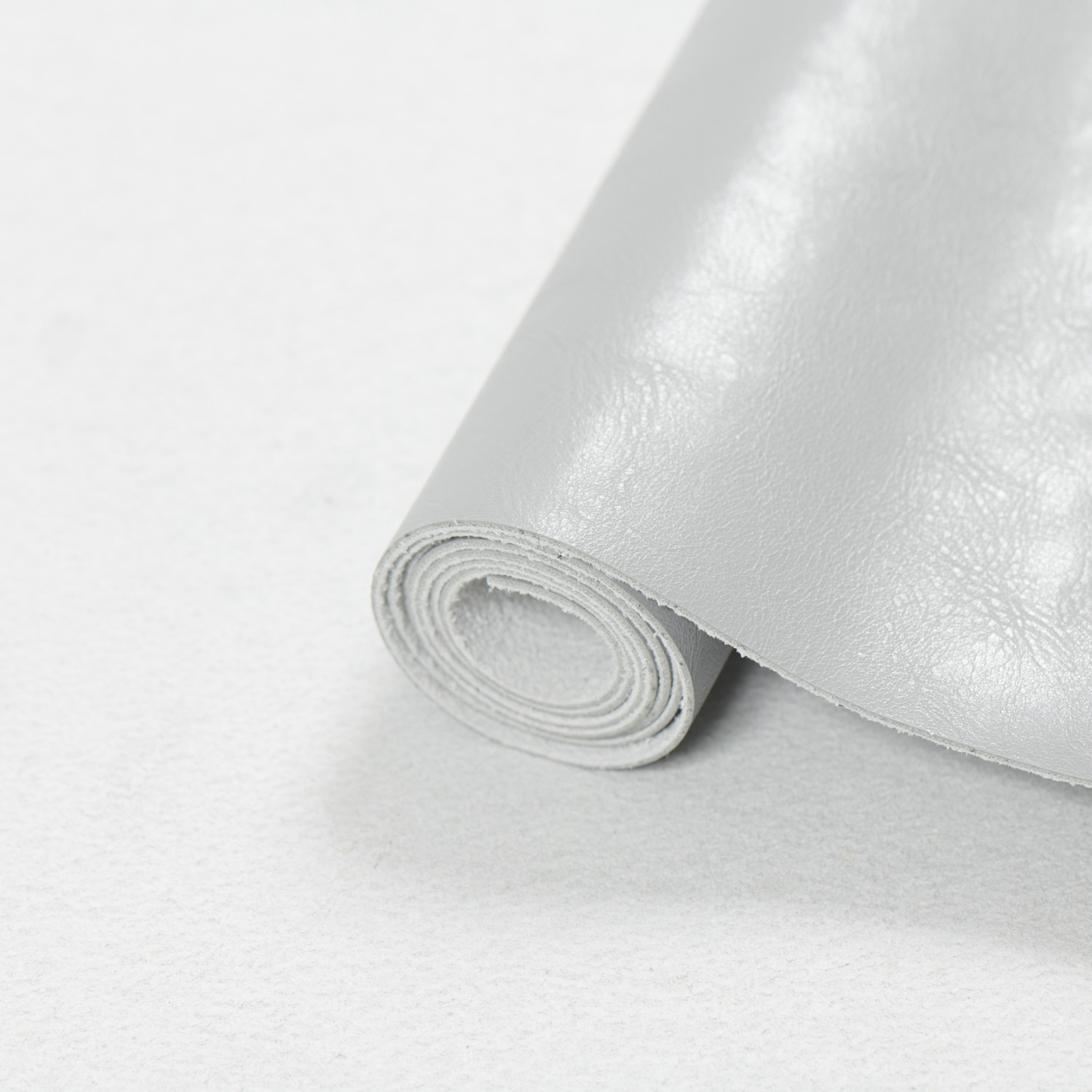

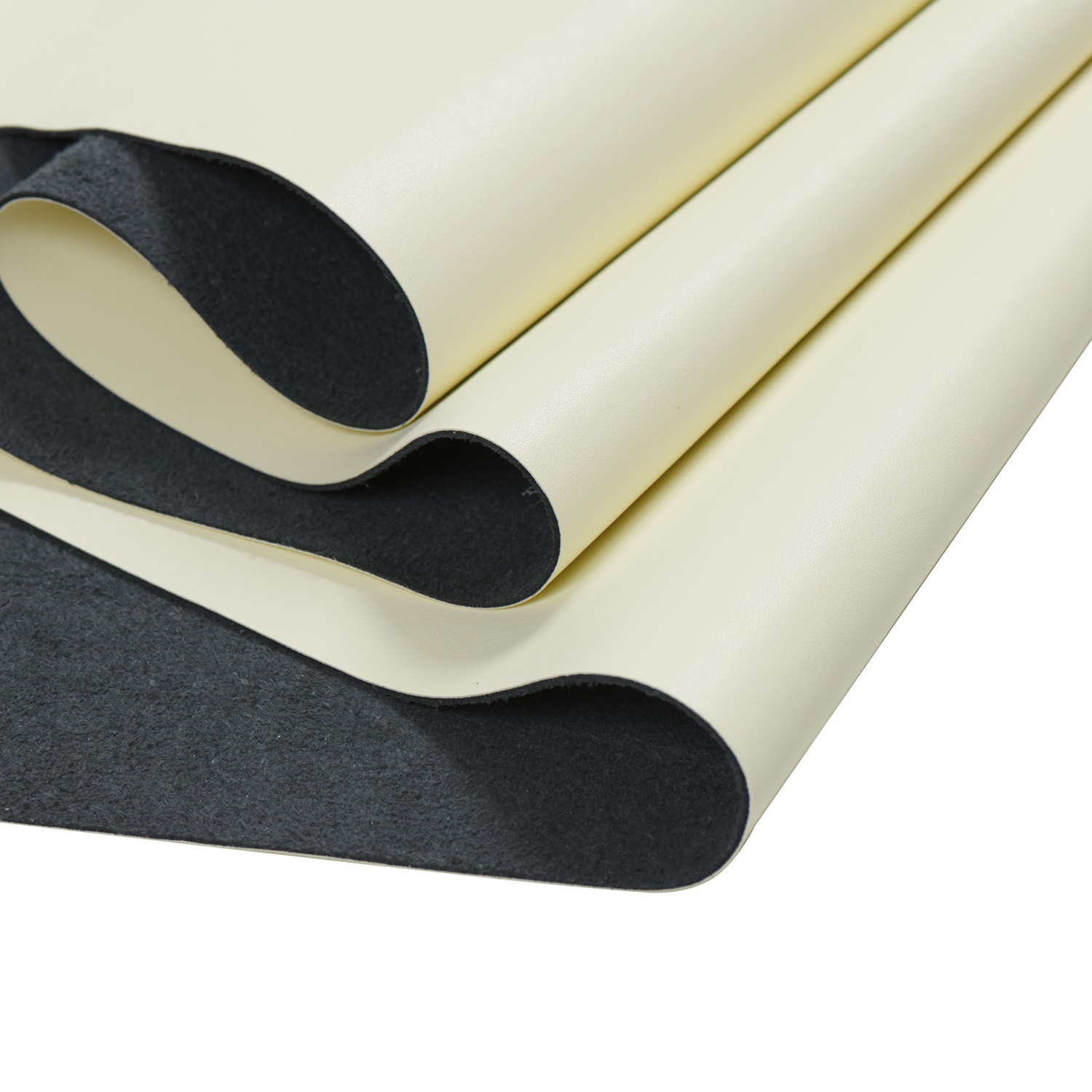

Our revolutionary process diverts leather waste from landfill to become sustainable, durable material that outperforms traditional leather in every way. Turning waste leather into fibers,entangling them around a high-performance recycled synthetic fibers using nothing but high pressure water. For a flexible, consistent and high-quality roll.

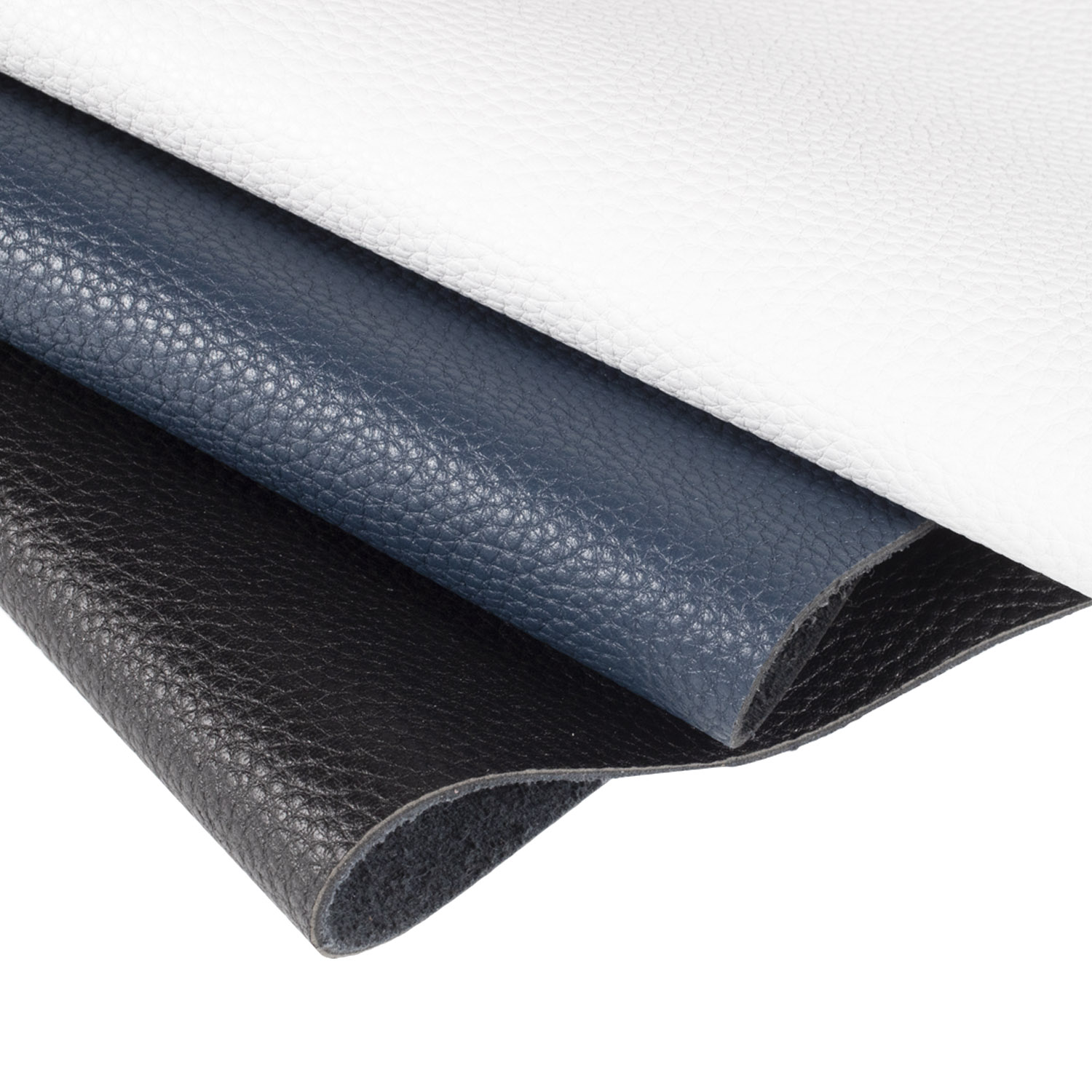

Leather scraps are ground into fibers.They are then built together with recycled syntethic fibers using nothing but the power of high perssure water.It is easier for manufacturers to cut and sew because of resulting in a material produced on a roll.It can be customized in any color with a number of textures to choose from .It delivers look and feel of traditional leather.But is less damaging to the planet.

How it`s made ?

Step 1: The Base materials of ELFA leather is leather shavings and trimmings.

Step 2: Leather shavings and trimmings undergo a fiberisation process which shreds and upgrades them into fine usable fibers .

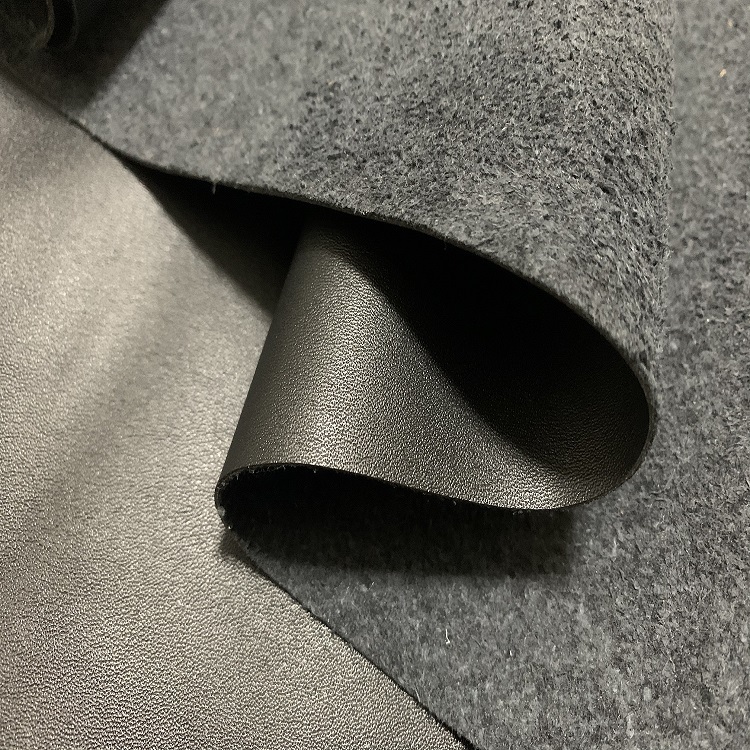

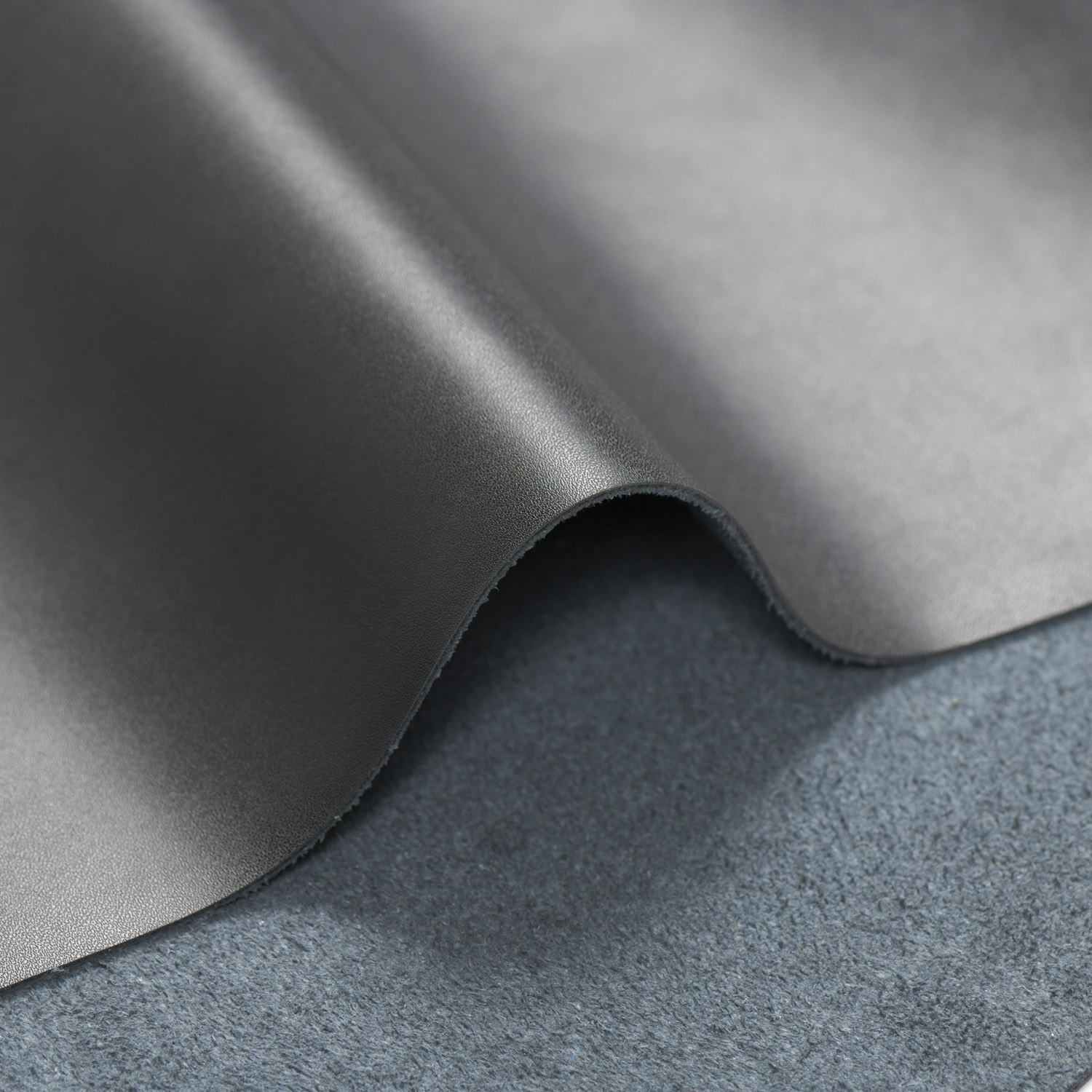

Step 3: Leather fibers are formed into two layers on both sides of recycled synthetic fibers.They are fastened with high pressure water jets rather than chemical adhesives.

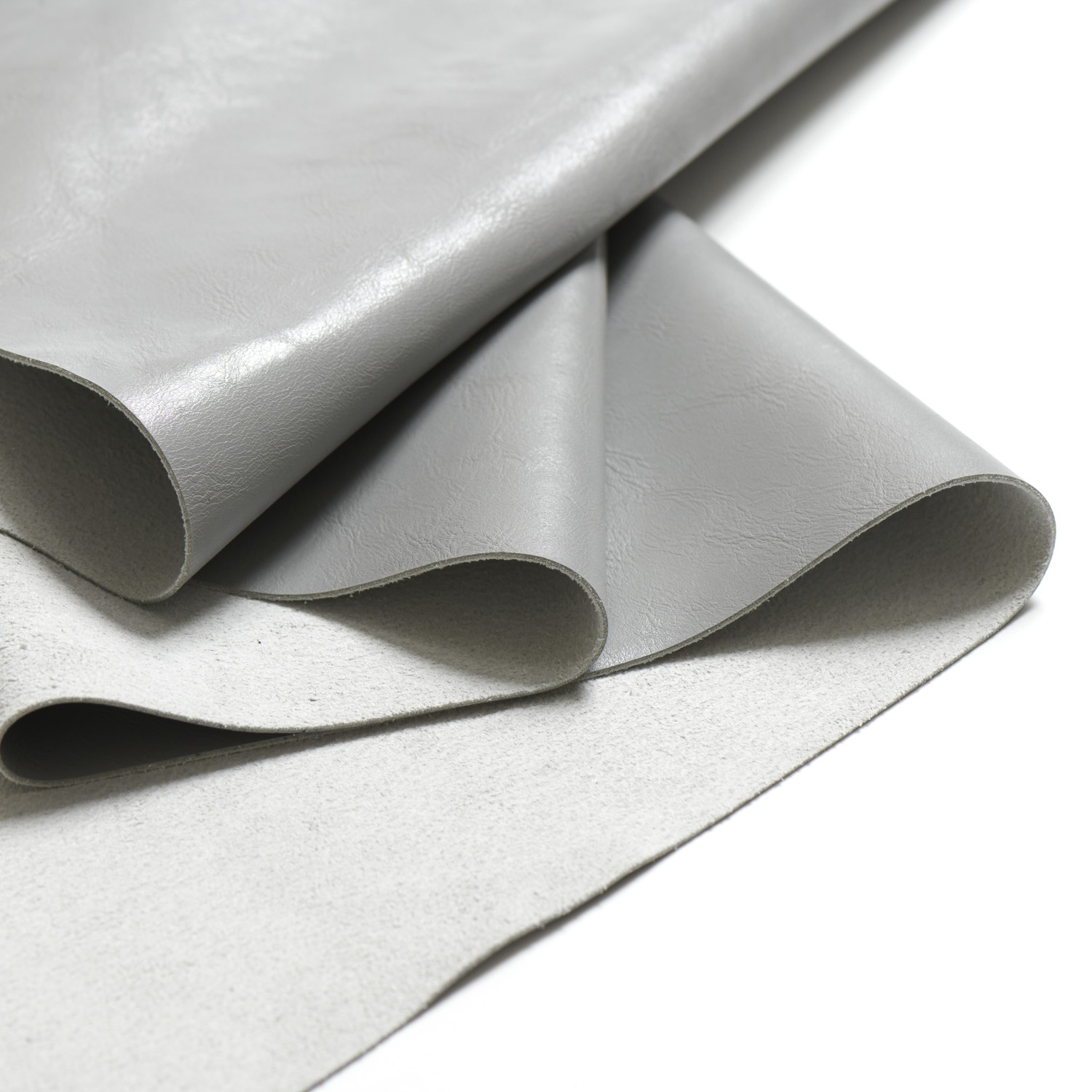

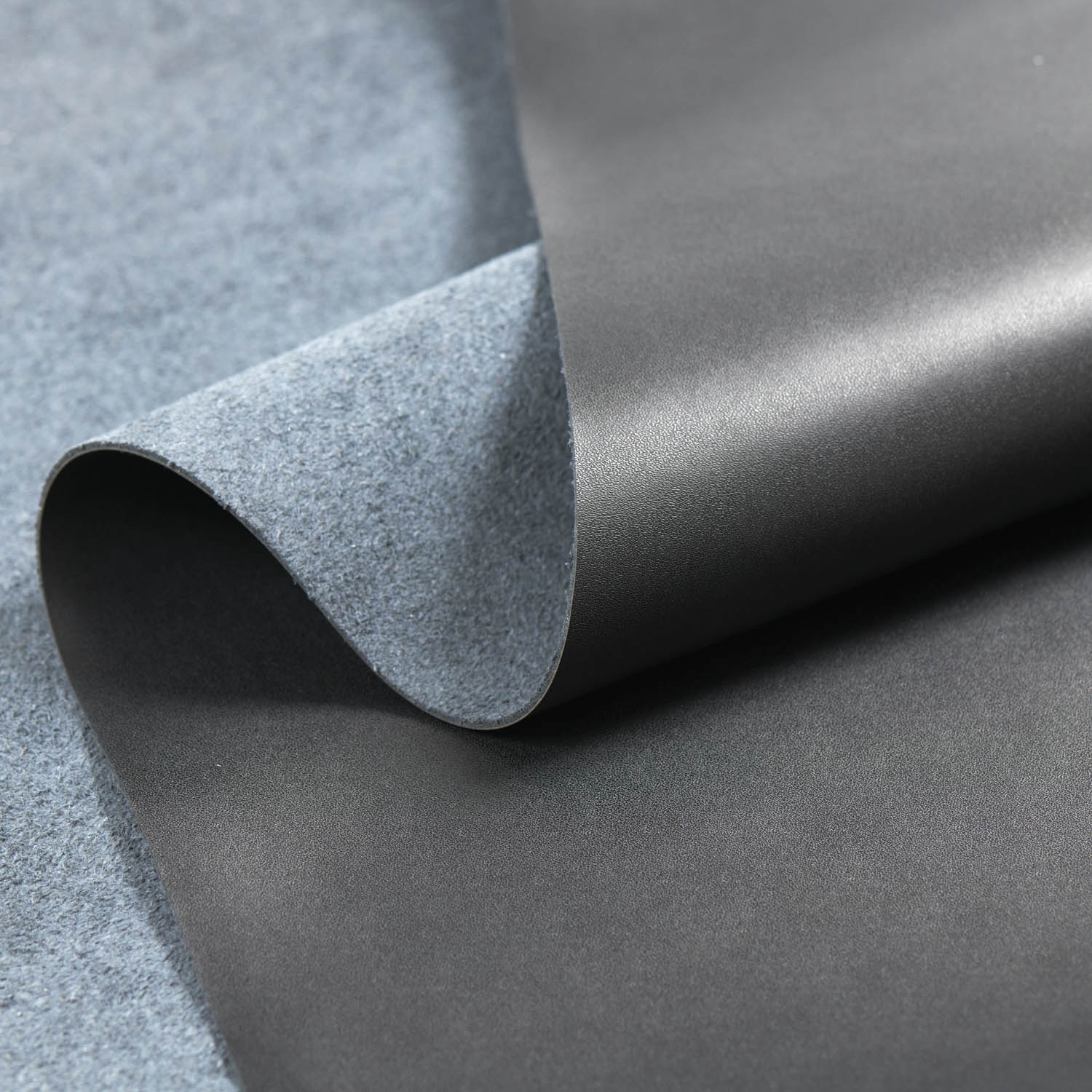

Step 4: After color impergnation ,a high performance finish coats the leather and a release paper template gives the surface a leather effect grain.

Step 5: After final inspection and quality assurance it is ready to be rolled . On a roll the leather is more functional to use and will produce less cuttings and wastages in the further use .

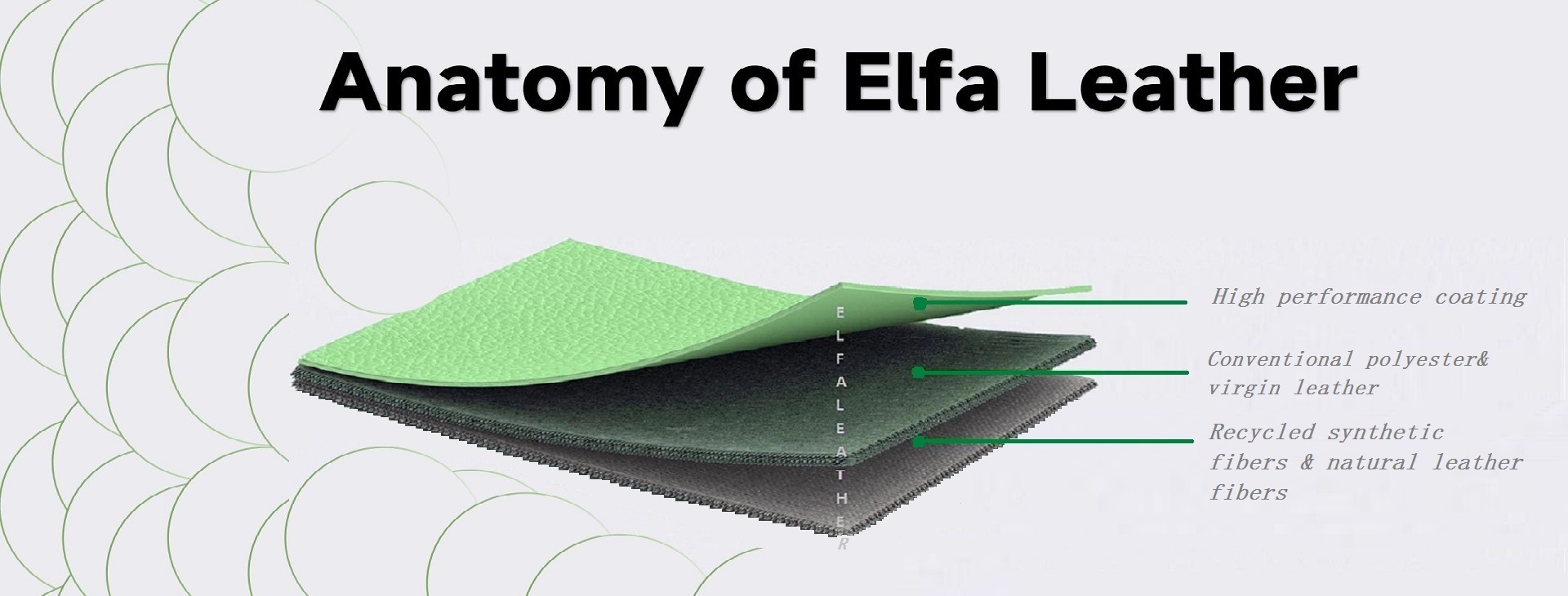

A revolutionary structure

ELFA Leather’s unique composite structure is versatile enough for any application. With variable performance characteristics, ELFA Leather can deliver added durability, softness, strength or even smart technology. Our unique structure combined with cutting-edge technology can deliver additional abrasion and stain resistance, or antimicrobial finishes. As well as infinite design opportunities, like embossing, digital prints, perforation and lamination.Our consistent rolls deliver a reliable material that can be trusted to go the distance when in-use. As well as providing many efficiencies in production from increased cutting yield to removal of hide inspection.

[/vc_column_text][/vc_column][/vc_row]