What is recycled leather and how is it made?

- Description

Description

With so many types of leather alternatives on the market, it can be hard to understand the differences between them. We’ll be taking a look at recycled leather – how does it square up to traditional leather? Is it sustainable? What’s the difference between recycled and bonded leather?

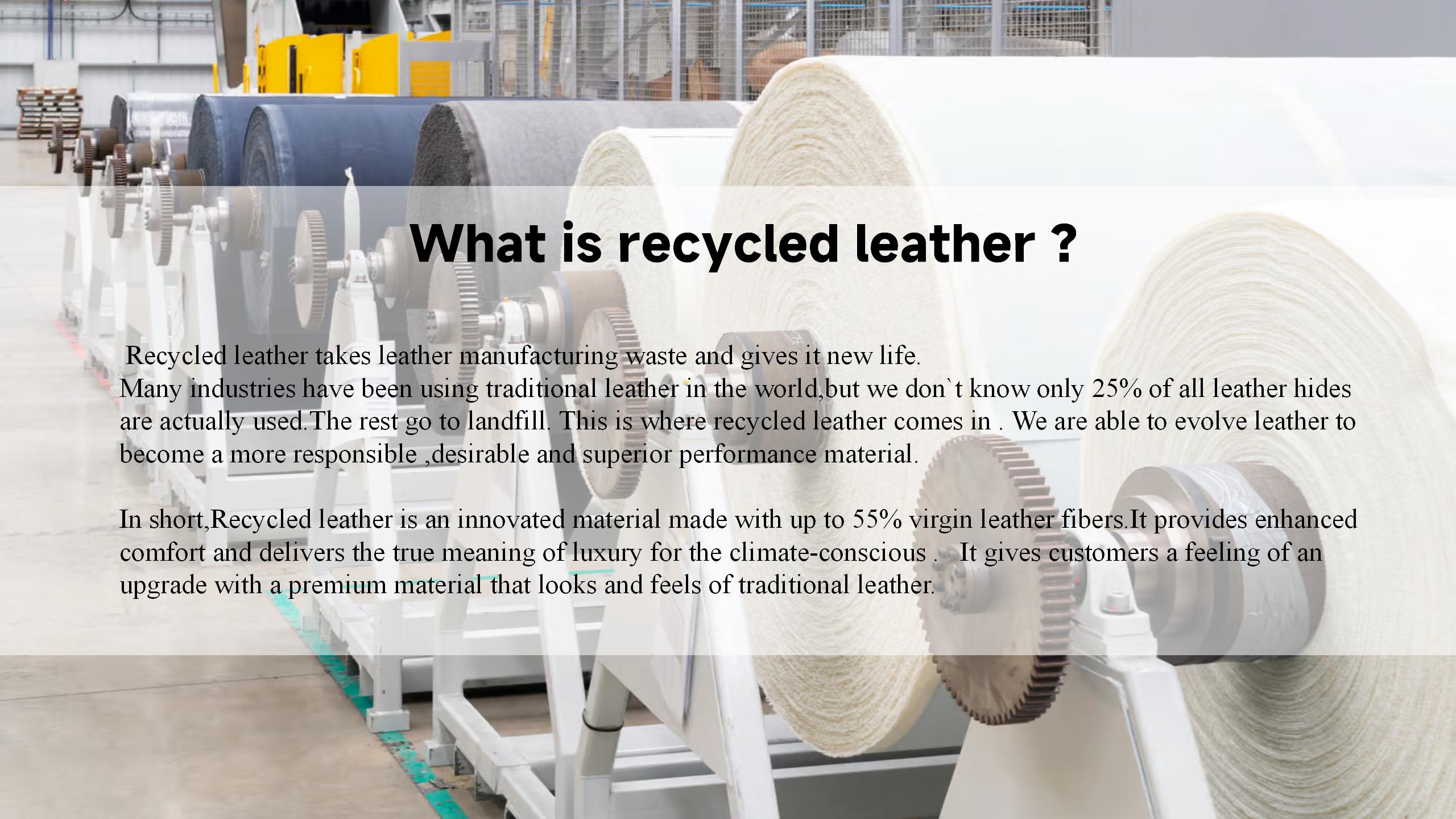

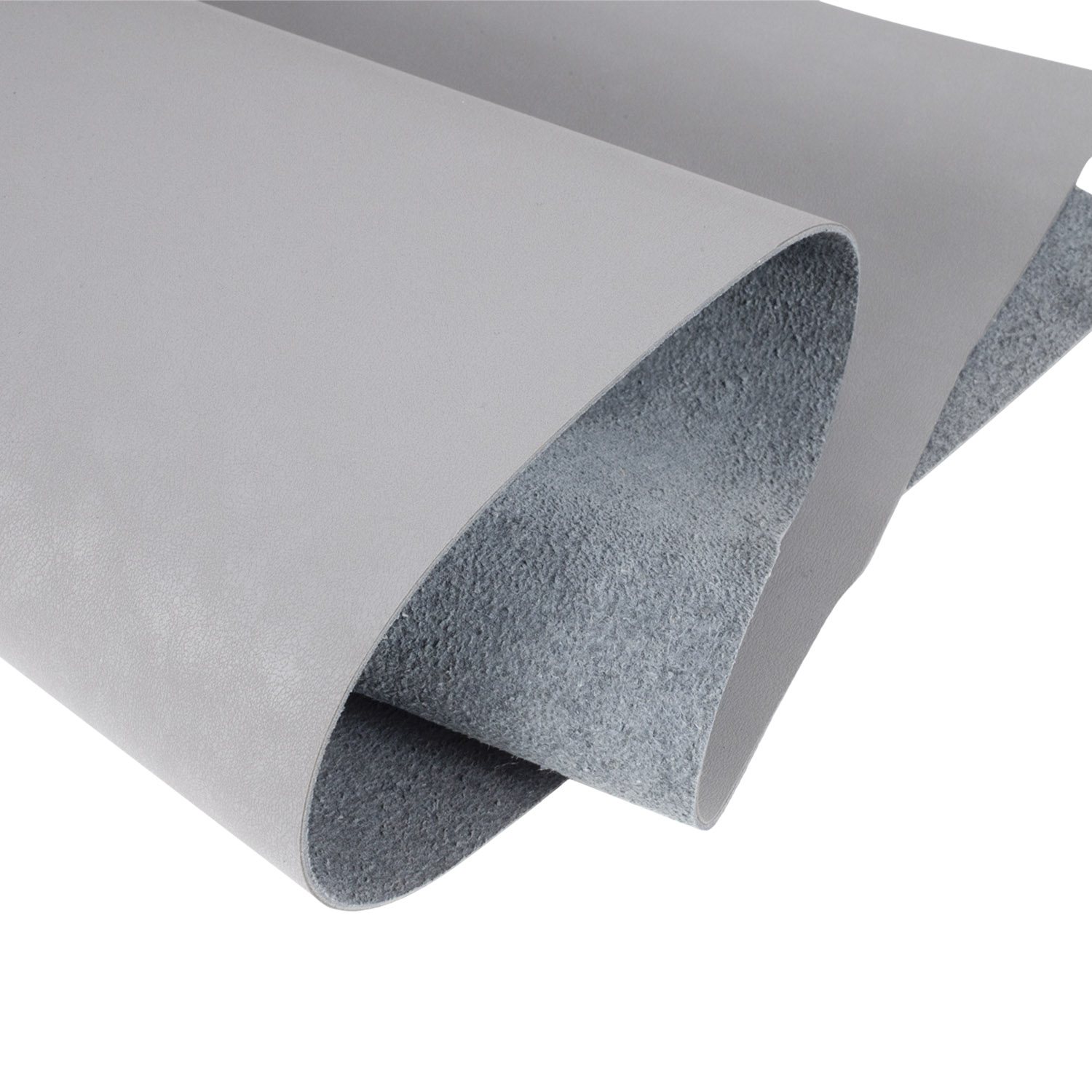

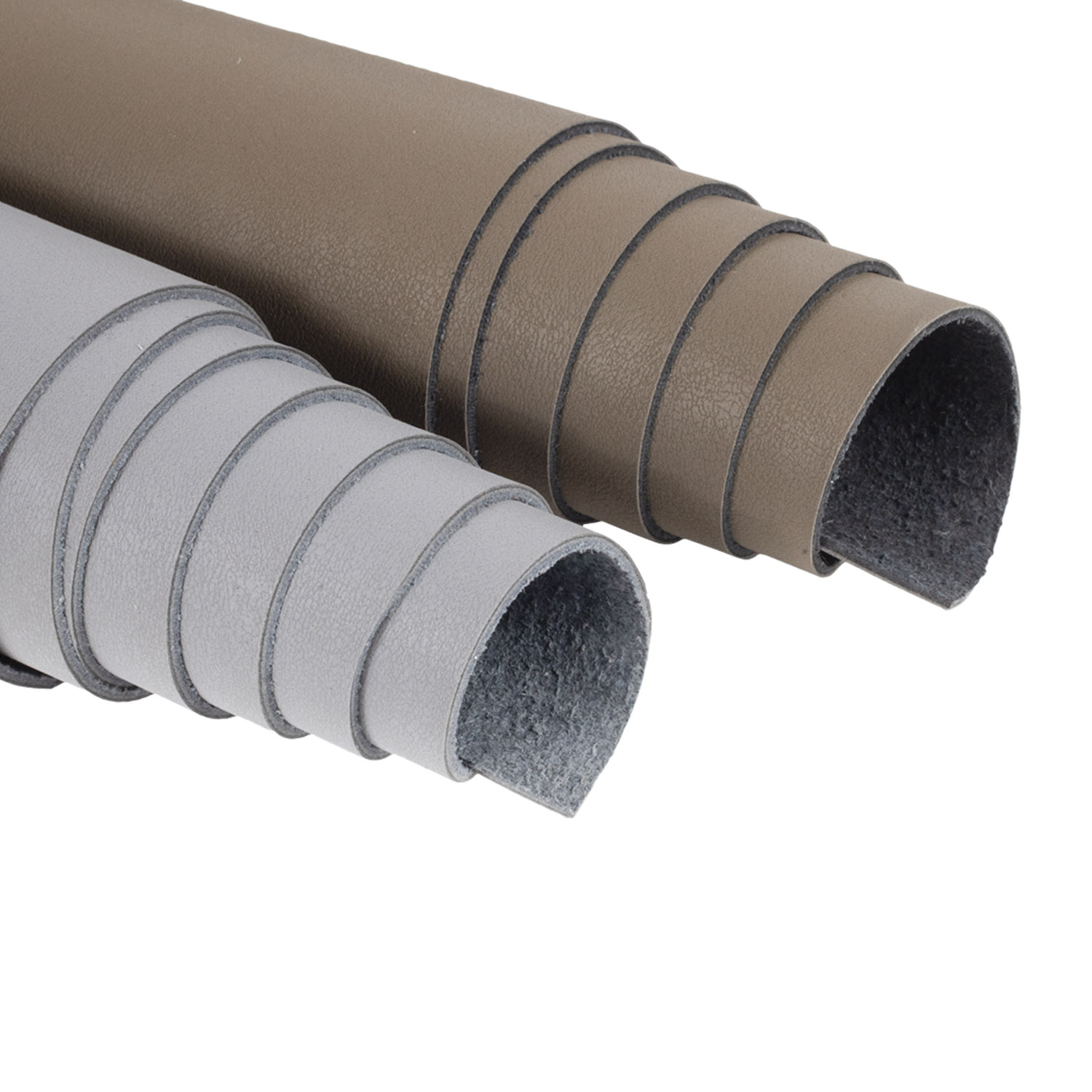

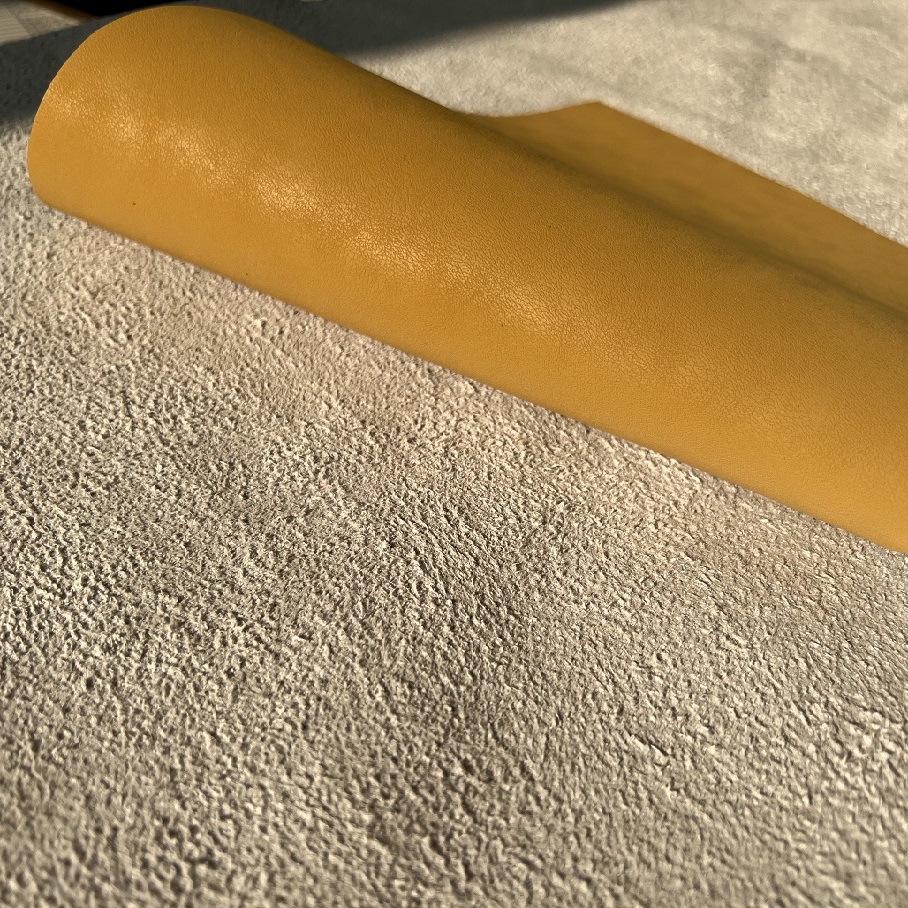

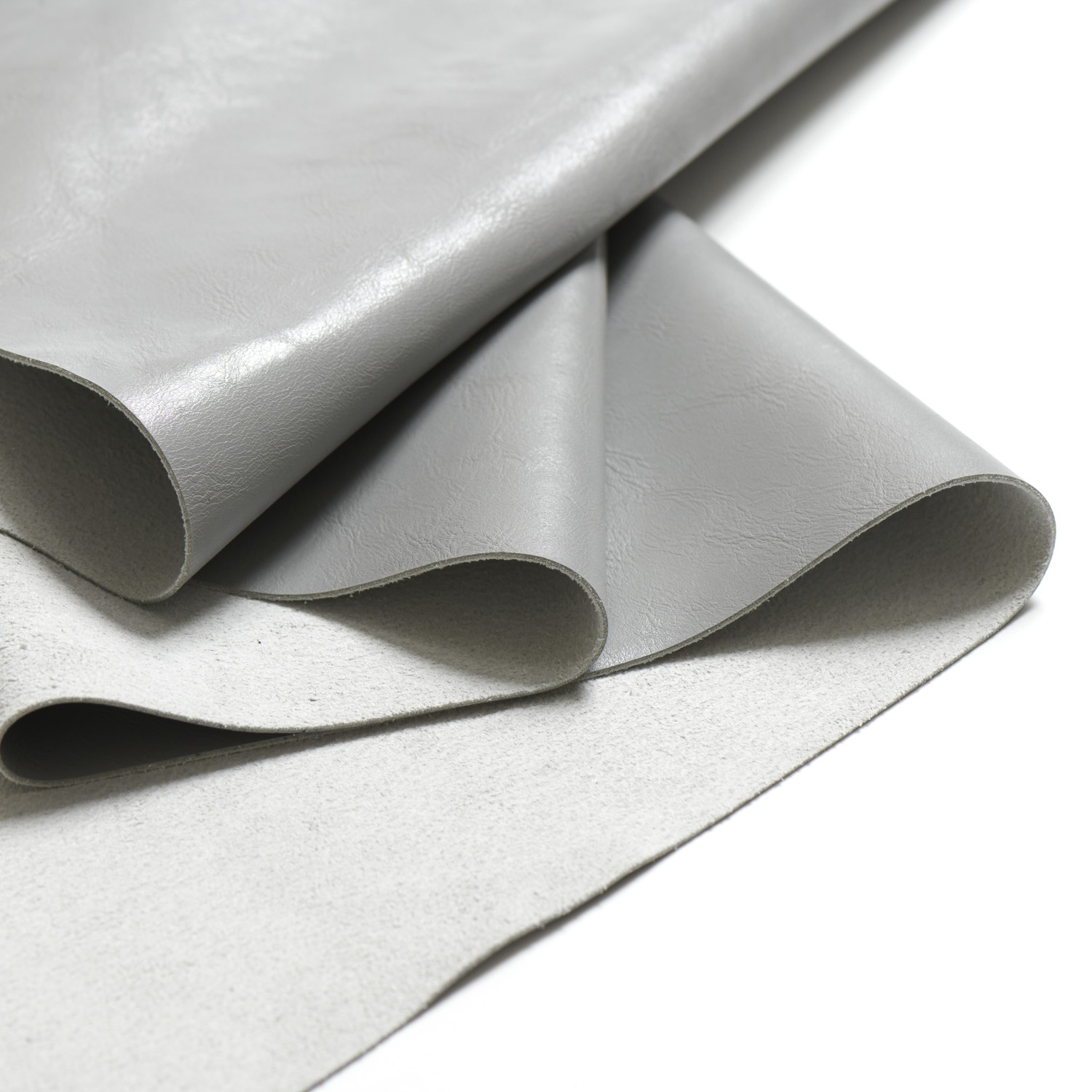

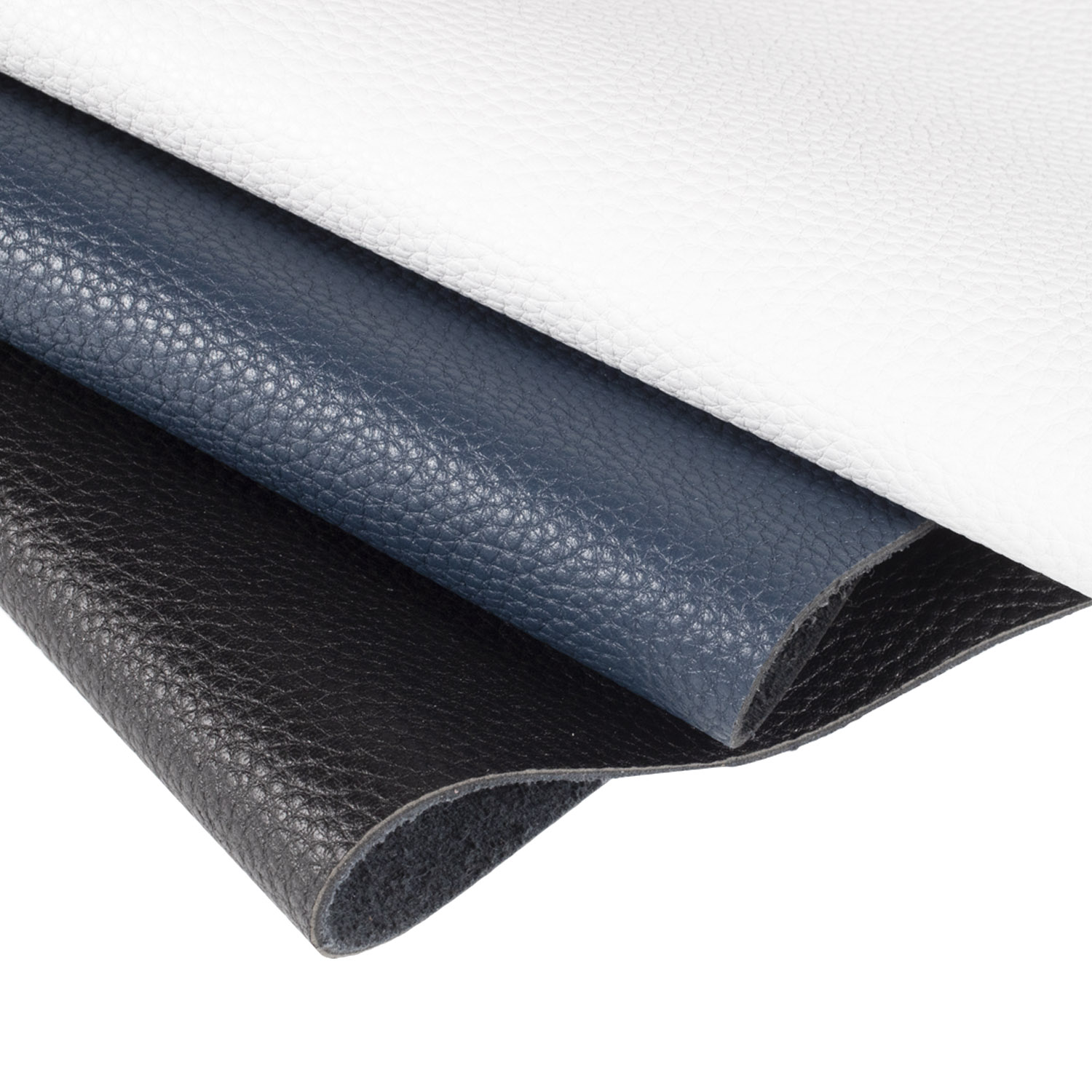

Recycled leather takes leather manufacturing waste and gives it new life.Many industries have been using leather due to its strength and longevity. And its association with luxury. Fashion industry is a big consumer of leather hides. As is the transport industry. Leather is so popular because it looks good and it lasts. Shockingly, though, only 25% of all leather hides are actually used. The rest go to landfill.This is where recycled leather comes in.So how is it made? Leather offcuts are ground into fibres. They are then reconstructed together and entangled with a high-performance core using nothing but the power of high-pressure water.Resulting in a material produced on a roll that’s easier for manufacturers to work with. It can be made in any colour with a range of textures to choose from. It looks and feels just like traditional leather. But is less damaging to the planet.Elfa Leather is our recycled leather. We are the original manufacturer of recycled, engineered leather tackling the widespread issue of excesive waste. Elfa Leather outperforms leather in every way. It’s made sustainably in a unique process. Offering change for the planet, luxury for consumers.

What makes Elfa Leather eco-friendly?

At Elfa Leather we’ve changed the narrative around using leather waste. We turn leather offcuts into a luxury material for the climate conscious. It’s sustainable, lightweight and long-lasting, without taking it out on the planet.(But is less damaging to the planet.)Elfa leather is environmentally-friendly for a number of reasons. So far we’ve recycled over 8,000 tonnes of leather waste (that’s almost as heavy as the Eiffel Tower). Our production method reduces carbon emissions by over 60% (compared to traditional leather).It also saves 55% of natural resources such as water and land. We use 100% renewable electricity and recycle 95% of the water used in our production process.A luxury material, that doesn’t cost the planet. Giving consumers a chance to enjoy luxury with a clear conscience. And all this data is backed by a full Life Cycle Assessment.We entangle leather fibres around a high-performance core using just high-pressure water. We call this process ‘hydroentanglement’. The result is elfa Leather. Recycled leather. Engineered sustainably.Here at Elfa Leather, we believe that too many of world’s limited resources are being unnecessarily wasted. By using a natural product that would otherwise be sent to landfill, we are evolving leather to become a more responsible, desirable and performance driven material – recycled leather.

Engineered for superior performance

In short, recycled leather is an advanced material made with up to 57% traditional leather fibres. It retains the luxurious look and feel of traditional leather at the same time providing enhanced comfort associated with soft trimmings.It’s engineered for performance meaning it is scuff and scratch resistant and due to controlled stretch it maintains its form and shape with no bagging, even after prolonged period of use. This translates into longer lifetime and reduced need for replacements.Our patented production process ensures consistent colour and gloss throughout the life of a product.Thanks to improved hygiene the product is low maintenance and presents a cost-effective solution, especially for high impact public spaces and transport operators.Recycled leather is a stable, predictable material which makes patterning and cutting more efficient with higher yield per roll and less waste as a result.

The pioneer of recycled leather

Driving material change

Taking more care of the world’s most previous resources builds better reputations. IN Fact.

We have saved thousands of tons of leather from going to landfill, instead using it to create material of choice for many global brands across multiple industries.

The production process of engineered leather not only uses 90% less water (compared to full grain leather) but 95% of water used is then recycled and used again. Fibers are entwined using only water and without the need for adhesives that can be harmful to the environment.

Going one step further, elfa leather`s wet production waste is converted into fertiliser used by local farmers while dry waste is recycled locally to further reduce our carbon footprint.

How it’s made ?

Taking our most precious commodity – water – we have developed and patented a manufacturing process that uses hydroentanglement technology to lock traditional leather fibers within a high-performance core.

Shavings, trimmings and split hides are diverted from landfill and then ground and filtered to produce individual leather fibres.

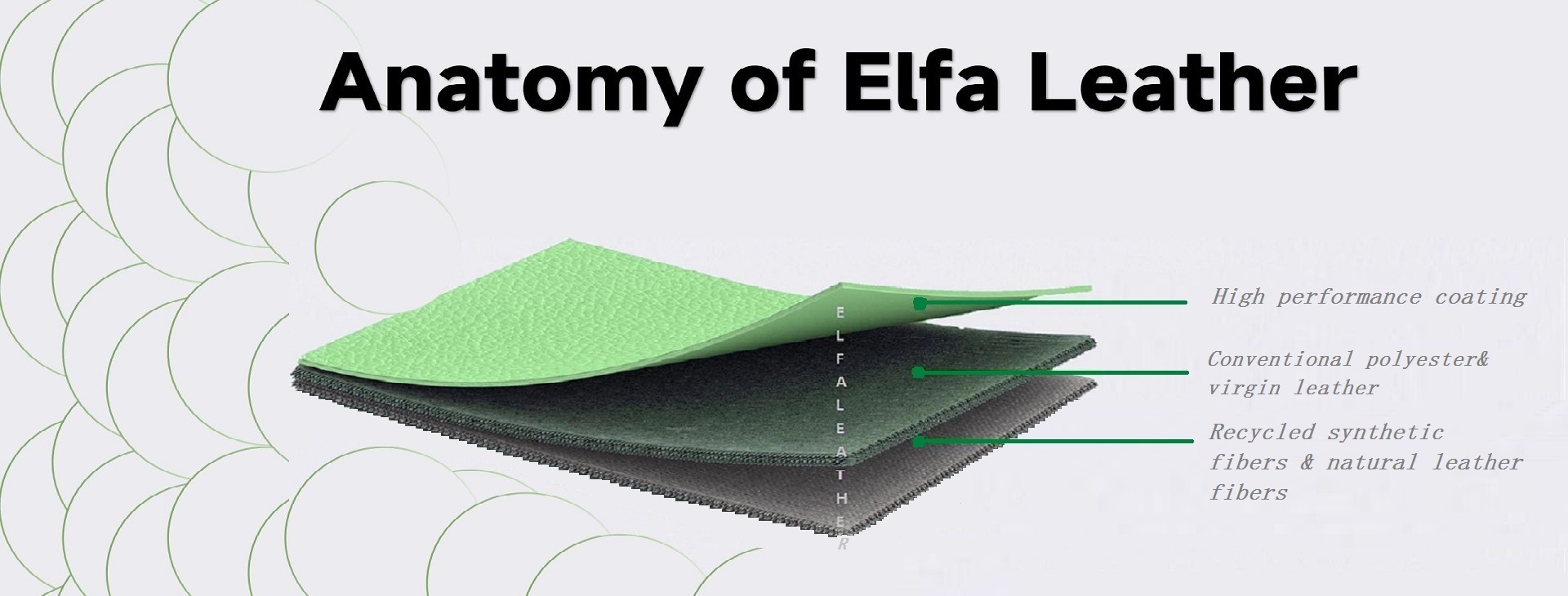

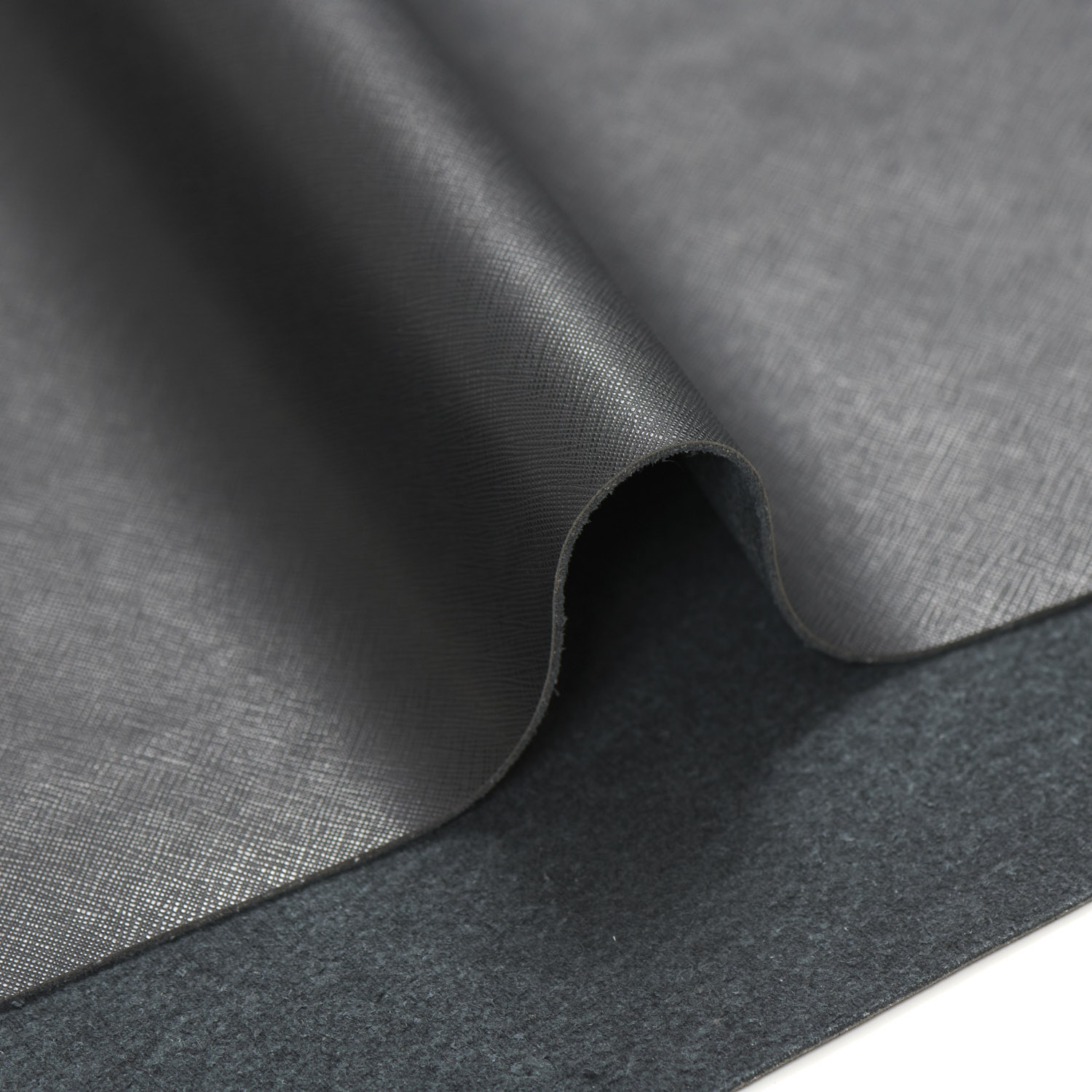

Strong conventional fibers and recycled synthetic fibers are laid between two webbed rolls of leather fibers, which are interlinked during the process of hydroentanglement. This negates the need for adhesives and the result is a structure similar to the one of traditional leather

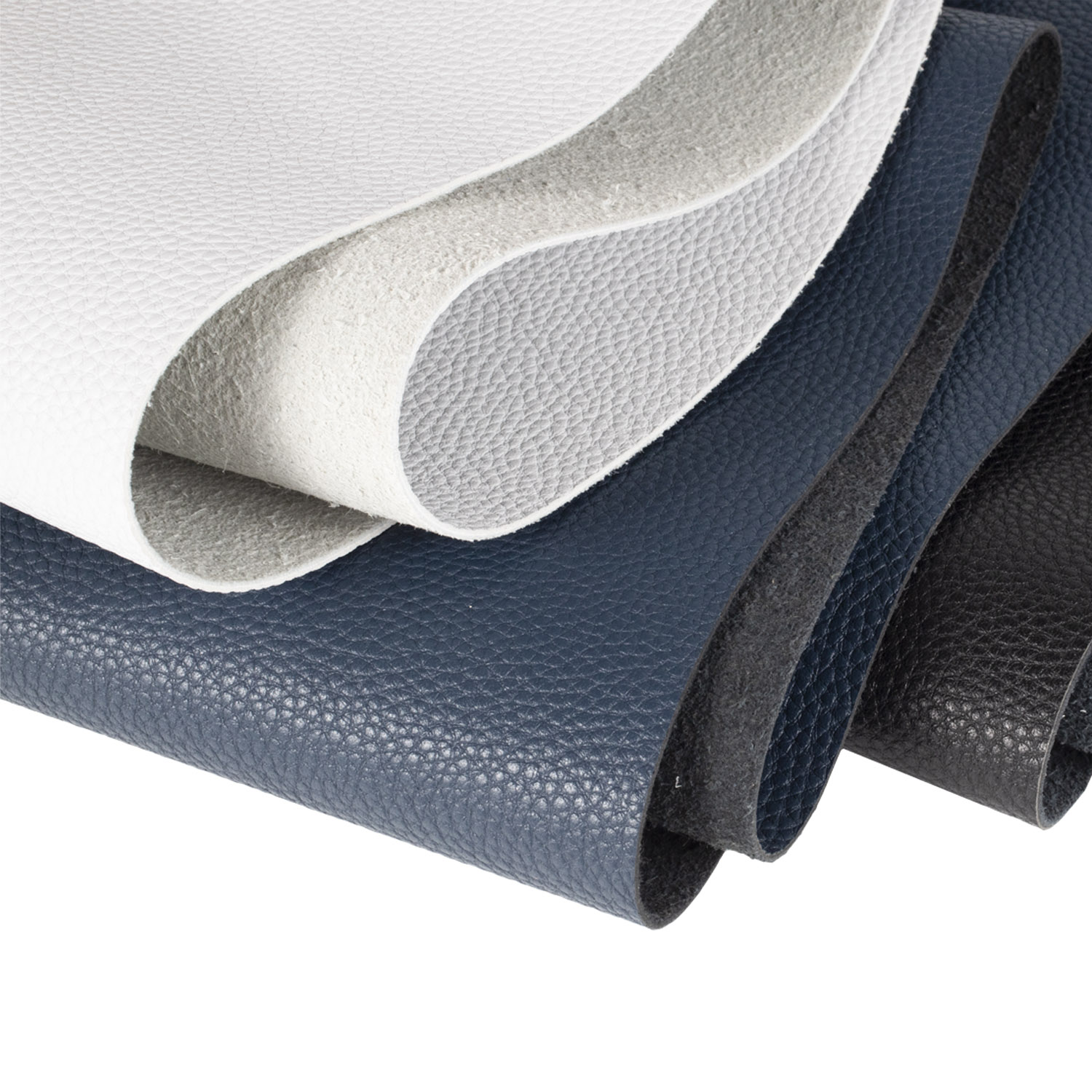

The substrate material is finished with the customer’s choice of colour and texture.

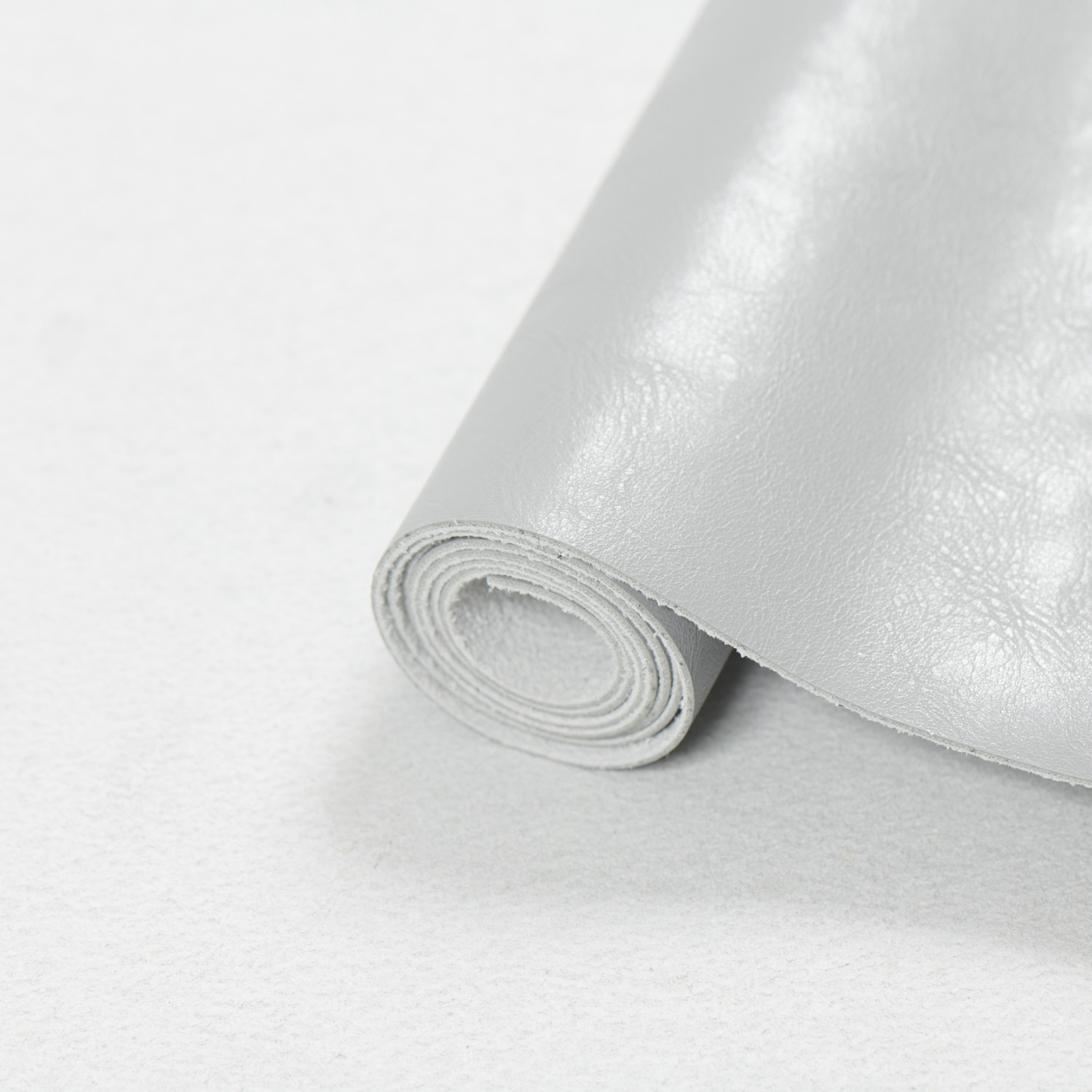

The result is recycled leather – a high performance material with all the benefits of traditional leather but supplied on a roll without natural markings or defects.

How to work with it?

Higher yield for cut and sew

recycled leather is more evolved than traditional leather and it’s got its own unique properties which make it behave different to its traditional, synthetic or textile alternatives. Thanks to a controlled stretch in one direction it retains its shape better when in use.The material is produced on a roll with even colour and gloss throughout meaning a higher yield and less waste. There is no need for high sewing machine foot pressure as the thickness and texture of the material is uniform although use of good quality tools is recommended. Conventional joining techniques can be used without issue and thanks to its strength, engineered leather can be trimmed within 2mm of stitch seams.

Easy to look after

Due to built in functionality, engineered leather is easy to clean eliminating frequent chemical cleaning requirements. Regular light cleaning using soft brush or vacuum to remove loose debris is recommended. This can be followed by wipe down with a light moist cloth.We test our product performance to the properties specified in the Elfa Leather Product Specifications. These specifications have been derived with the assistance of recognised independent Specialist Trade Associations, and Consultants in the Industry. Thanks to our zero compromise on quality with 100% performance approach, we are able to provide brands with competitive advantage.